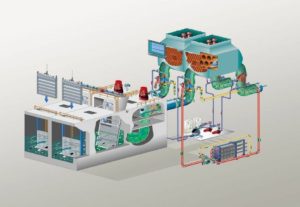

As the exclusive distributor of the Taprogge cleaning systems , spare parts and claening balls in Poland, we want to present the cleaning systems with flexible rubber sponges permanently circulating in the system , which solve problems with cleanliness of the inner surface and maintain the heat transfer of the heat exchanger – short payback time of 0.5 till 2 years.

As the exclusive distributor of the Taprogge cleaning systems , spare parts and claening balls in Poland, we want to present the cleaning systems with flexible rubber sponges permanently circulating in the system , which solve problems with cleanliness of the inner surface and maintain the heat transfer of the heat exchanger – short payback time of 0.5 till 2 years.

Micro fouling causes a rise of the heat consumption of a turbine unit by between 1 and 2%.

Taprogge cleaning/ filtration systems application:

- Cooling water circuits of power stations , seawater desalination plants and in industry yield thermal performance gains.

- Major and auxiliary power cooling plant circuits: power plants, chemical, petrochemical, steel industry etc.

We offer the Taprogge solutions for new investments.

Advantages:

Montaż Instalacji pozwala osiągnąć następujące efekty:

- Efficiency and availability by permanently constant heat transfer of the heat exchanger and condensers

- Reduction of primary energy costs , increase turbine output

- Relief of environmental burden by saved fuel ( reduction SO2, NOx, CO2)

- Equipement longer lifetime

- Reduces corrosion in the heat exchangers

- No unplanned stand-by

- Wide range of claning balls